H-11 (1.2343) is a 5% chromium hot work tool steel. Compared to H13, H11 steel has less vanadium giving it higher toughness, with some reduction in wear resistance and tamper resistance. H11 steel has excellent dimensional stability during heat treatment.

H-11 & H-11M Similar/Equivalent Steel Grades :

| CHINA | BRAZIL | AUSTRIA | GERMANY | |

| TG | VILLARES | BOHLER | DEW | GRODITZ |

| H 11 | TENAX 300 | W300 | 1.2343 | 1.2343 VICTORY |

| SLOVANIA | JAPAN | TAIWAN | CHEZ. REP |

| RAVNE | SANYO | GLORIA | POLDI |

| UTOP M01-EFS | QDA61 | GMH11 | TLH EFS |

Steel Properties : High hot tensile strength and toughness. Good thermal to hot cracking. Can be water-cooled to a limited extent.

Applications : Hot-work tool steel for universal use. Pressure casting dies and metal extrusion tools for processing light metals, forging dies, moulds, screws and barrels for plastic processing, shrink rings, hot-shear blades.

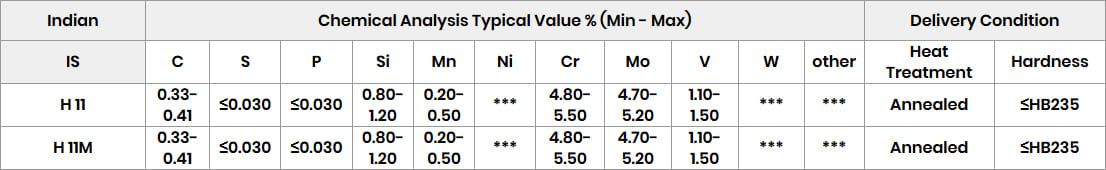

Chemical Composition: (%)

Production Process :

Round Bar :

Flat Bar :

| UT Standard : | Reduction Ratio : | Delivery Status : |

| SEP 1921, (DEC.84)E/e | As 1:4 or 1:5 | in annealed condition. |

Sizes of Round Bars :

| Cold Drawn/Ground Bar | Hot Rolled Annealed & Peeled Bar | Forged + Annealed + Turned Bar |

| Φ 2.0 - 14.4mm | Φ 14.5 - 80.0mm | Φ 81.0 - 810.0mm |

Sizes of Hot Rolled Flat Bars / Sand Blasted & Machined Straight :

| Thickness | Width |

| 5mm - 410mm | 10mm - 810mm |

HEAT TREATMENT CONDITION :

Quenching temperature : 1020-1050℃

Cooling Medium : air-cooling

Tempering temperature : 550-650℃

Tempering times : 2Times, the tempering temperature in the second time should be lower than in first time

Tempering Hardness : 47-48 HRC.

| Tempering°C | 500°C | 550°C | 600°C |

| HRC | HRC56 | HRC54 | HRC50 |